Bay windows and external wall insulation – How does it Work?

External insulation is often carried out on properties that were originally built in the 1900-1930s period. This is when the majority of solid brick properties are from. Many of these homes have bay windows with tiling around them, and in some cases have entire walls that have been tiled. We get asked about these areas and what we can do with them in terms of insulation, so in this blog we are going to take you through the options.

Can you just insulate up to the area and leave it untouched?

The simplest and cheapest option for the tiled areas is to not insulate them and leave them as they are. The tiled bays are often really small areas anyway, and the extra cost to carry out works on these is going to be more than a standard piece of rendered wall. But they are also often the most exposed and can sometime be a single brick thick, so they are usually a cold spot in need of work.

Can I remove the tiles completely and have a rendered wall?

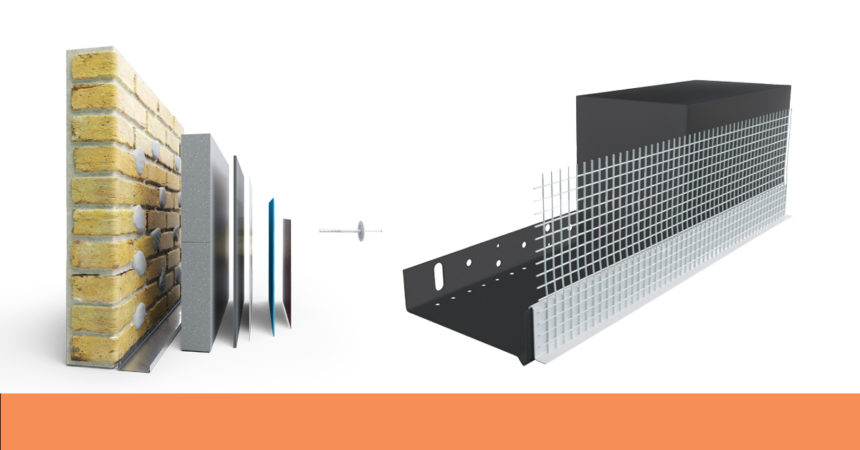

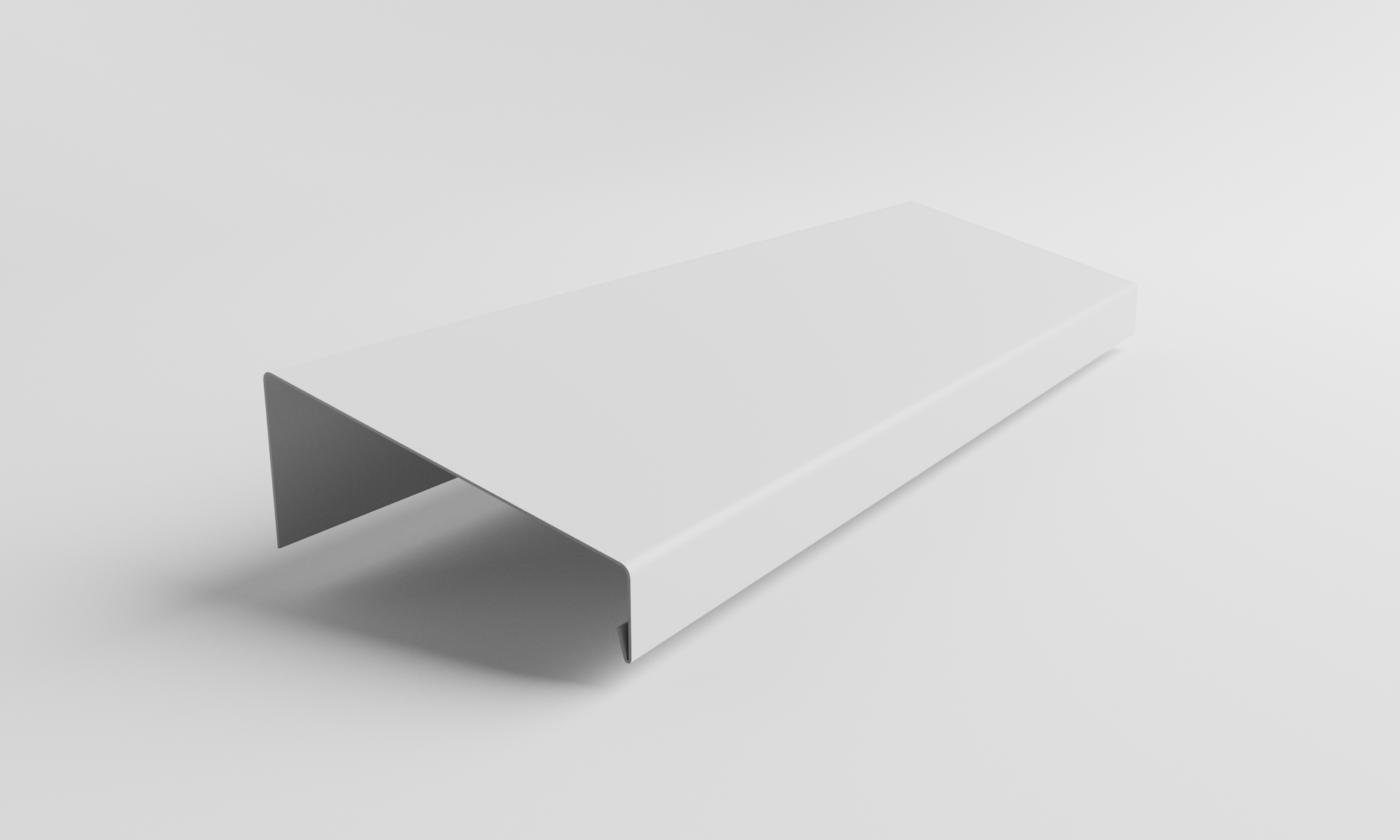

The easiest option to insulate these areas is to remove the existing tiles and add a layer of insulation. This is then rendered to make the finish the same as the rest of the house. The cost of this is only a little more than the works on the main wall, at least per square meter.

It can be a really good option, especially if other properties on the street have rendered bays – it won;t look out of place. The render won’t need as much cleaning as the tiles either, so there is a reduced maintenance cost.

Can I reuse the tiles already on the wall?

If you are going to take the tiles off the wall in order to insulate, many of the tiles are going to become damaged as part of the removal process. The tiles are often old and tired looking anyway, so we would usually look to add new tiles once the insulation is on, if a tiled finish is what you are after.

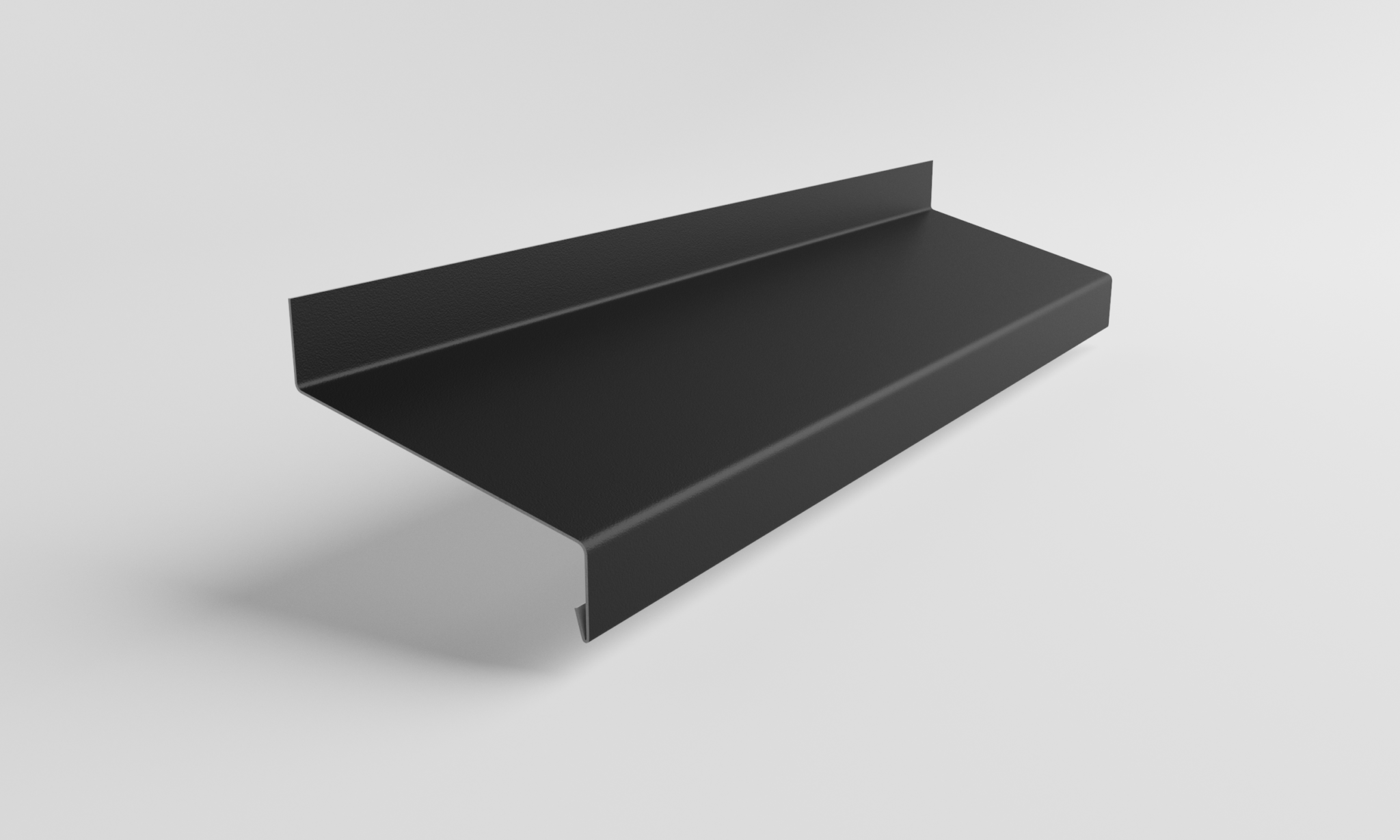

Can I insulate and retile the area?

Absolutely. This can produce some really great looking results, as can be seen on our recent Harrow installation. When you compare the new tiling to the neighbours, the stark difference in the colour after all those years of fading and exposure is amazing. The finish looks really good as well.

How do you retile and how does it look?

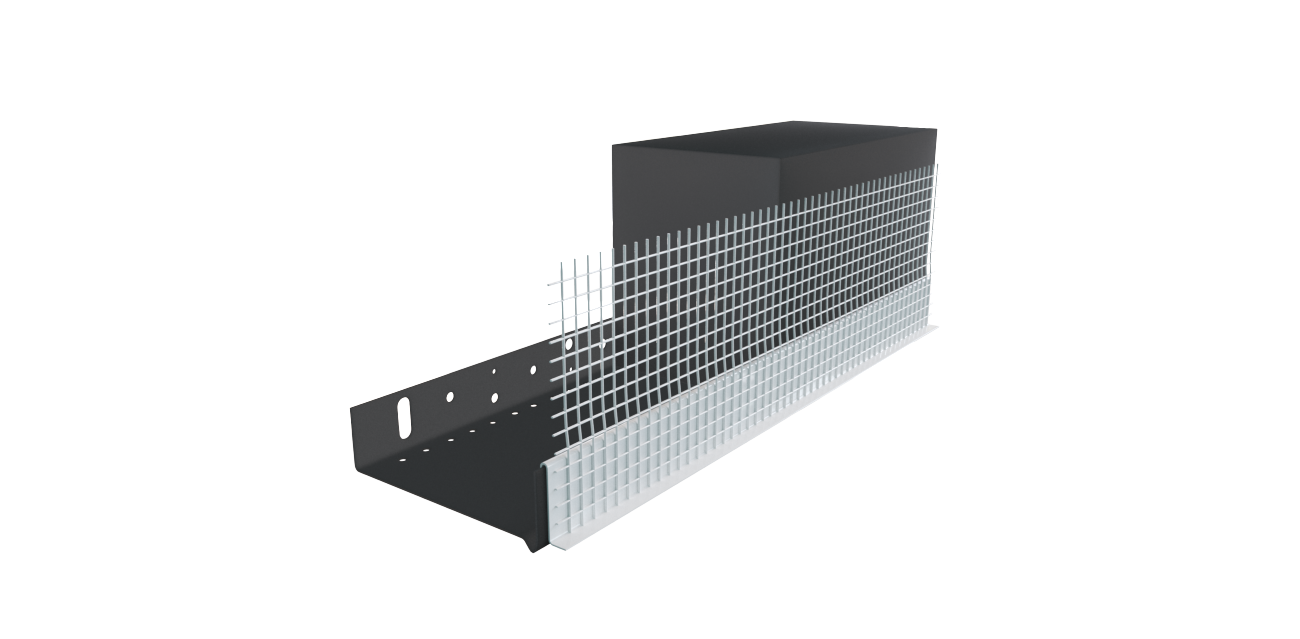

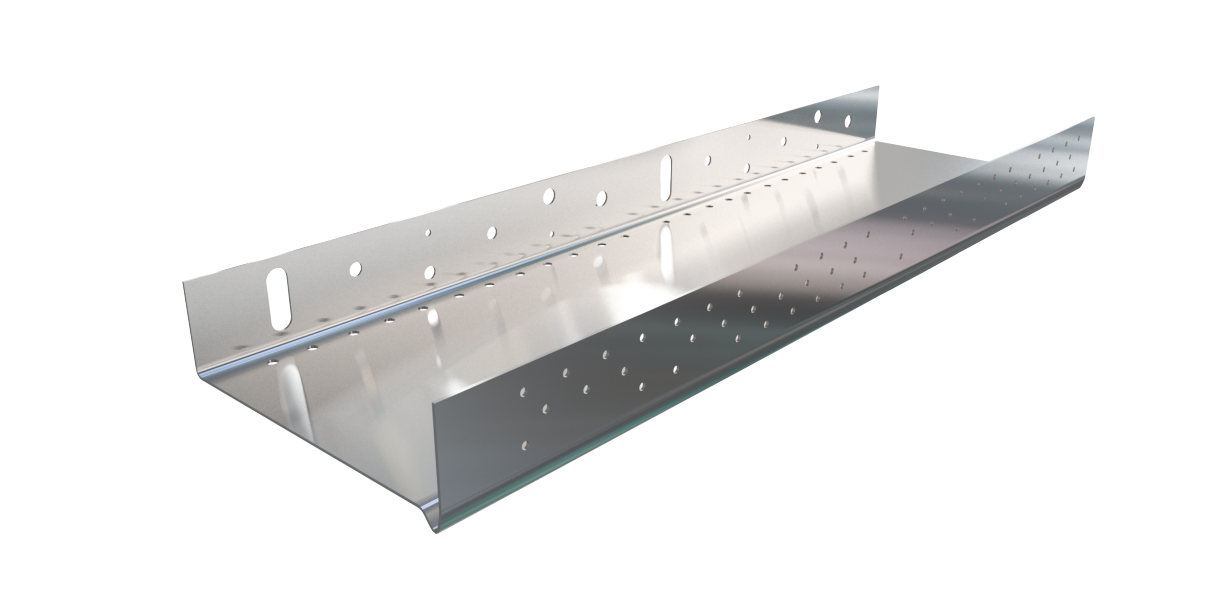

The retiling process is relatively straight forward, if a little time consuming. The tiles are stripped off and the timber batons underneath are usually removed – although it does depend on the type of surface you have underneath. The wall is then insulated, usually with rigid PIR board insulation, mechanically fixed to the wall. On top of this layer new timber batons are added to support the new tiles. Tiles ar then hung just like you would on a normal tiling job – the only difference is the new layer of insulation below.

This is obviously a lot more work and extra materials compared to an average render installation, so you should expect to pay more for the work. As you can see by some of the photos, it does leave a great looking finish though. Tiles get tired and faded over the years, often with build ups of biological growth as well as damage from wear and tear. Some tiles are 50 years old or more, and it really shows. Hanging new tiles will make a big impact on the appearance of the property, so we would be happy to give you this option when we come to quote.

As always we ask that you give us a call, and we will be happy to take a look at your property and provide a quote.