Is Insulating External Walls With Wool Worth It?

Insulating solid walls or any other type of wall that has poor insulation is absolutely the optimal thing to do – not only from an energy efficiency perspective but if undertaken externally will also give your tired façade a renewed look.

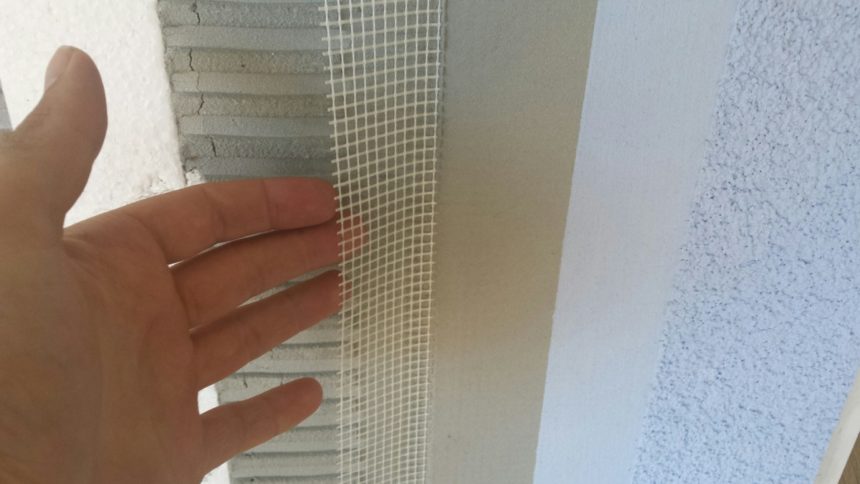

There is a lot to be said about the materials that are used for this insulating process and many system designers out there will argue their point-of-view. If you are insulating the walls externally you can use a number of materials including: expanded polystyrene, mineral or rock wool, cork and phenolic resin. If the process is internal you could use mineral or rock wool, as well as sheep wool and phenolic resin.

Although wool insulation for walls is not the most popular product as yet, it certainly has advantages over other materials.

Mineral wool insulation is breathable

The mineral wool system is what the industry refers to as “open vapour system”, which means that effectively moisture particles can find a way from one side to the other through the material and the masonry walls. Do not confuse this with being prone to damp issues – an open vapour system will absorb moisture in the wool fibres and dissipate this through the breathable top coat of the render that was installed.

If your brick ties are very tired and the brick itself is prone to moisture, then this could be the solution for you. Effectively the damaged brick may never be fully dry when applying the wool insulation system. If you then install the open vapour system like wool it will allow the moisture the ability to dissipate through the material and out to dry, making this insulation material really good for these types of scenarios.

A closed vapour system on the other hand stops like EPS the moisture escaping on the outside which is why in some cases when installed on properties it shows signs of damp on the inside.