Why is fibre glass mesh so important on rendering systems

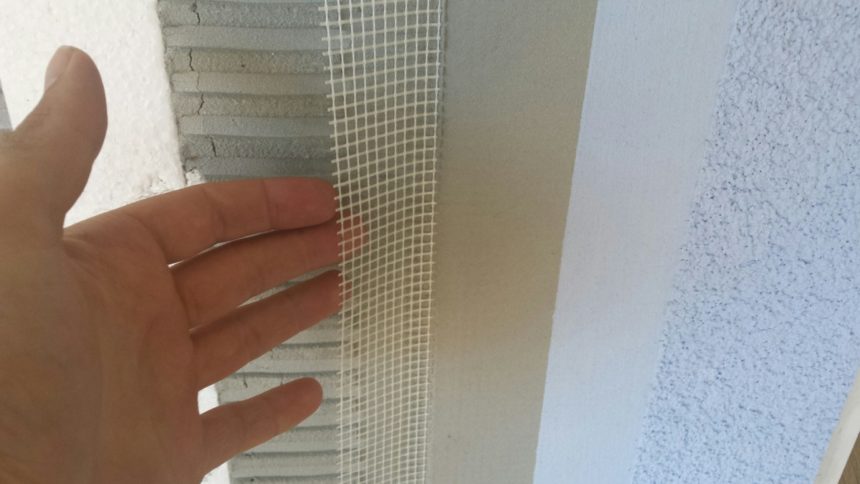

If you have had the solid wall insulation installed or a new rendering system put onto your wall, then you may have seen the fitters emphasise how important it is for them to install the fibre glass mesh. When the piece is being installed it is skilfully sunk into a thick layer of adhesive mortar. A notched trowel leaves a nice smooth surface for the top coat to be applied.

For insulation systems, it is an essential piece of kit that is installed on top of the insulation and just under the final render. It binds the whole thing together and gives the new insulated wall much needed flexibility.

In the rest of the blog we spend a bit of time going over some of the benefits of this piece of kit. Hopefully if you are a builder or an architect, you will take this away, and potentially look to integrate some of these ideas onto your future projects.

Gives the finish strength and flexibility

An obvious benefit of the fibre glass mesh on rendering systems is its ability to bind the insulation layer or the existing wall into a nice and strong finish. When the mesh is sunk into the adhesive basecoat, it provides a solid hardened layer. Should anything happen to the top coat, the fibre glass mesh interwoven into the adhesive will hopefully not fail. This allows you to repair any parts of the damaged surface render.

If you ever feel a piece of EWI fibreglass mesh in your hands, then try to pull it, you will notice how flexible the system is. Now imagine if something happened to the property itself. For example, you have some movement around the window lintels, or the property moves. The mesh is designed to absorb most of that impact. By stretching out, it will allow you to keep the surface looking visually intact.

According to the EWI Pro (system designer) installation guide, fibre glass mesh sheets should be installed with an overlap rather than butting up against one another. Refer to their training guide for more details.

Enforces weak points around openings

Most system providers stipulate how the mesh should be installed properly. Why is this important?

The weakest point of a building is around the openings, especially around windows and doors. This is logical because on windows and doors you have lintels and frames holding down a lot of weight from the other building materials. The key thing then is to ensure those areas are properly enforced. How does the fibre glass mesh help?

EWI system designers like EWI Pro will stipulate a set of installation procedures and treatments around openings to link back to the first features, which are strength and flexibility. For example, the EWI Pro system advises fitters to cut out small pieces of mesh and overlap the edges of openings at 45’ angles.

If the fitters strictly follow these instructions then there is no reason to suggest that the product will not do as it says on the tin.

Impact resistance

If you have ever held a piece of insulating polystyrene or a slab of mineral wool, you may have wondered how on earth will that stuff stay robust on my walls.

A standard 125g piece of mesh sunk into the basecoat will give the system some impact resistance. However, on its own, it may not withstand constant pressure or high impact. So what can actually be done to give the system additional impact resistance?

You can go two ways about it; one, you can double up the mesh (install another layer on top the existing one). Or secondly, use “Panzer” mesh, which is 335g which is designed for more robustness.

Obviously if you take a sledge hammer and smash into the wall or you drive your car into your newly insulated bay, there may not be a lot out there to mitigate from the effects of that. You will not just dent the insulation but a heck of a lot more.

On rendering new builds

If you are embarking upon a new build project, whether it is from scratch or extending an existing property ensure you give the external elements as much attention as you do with the internal ones. In this instance we want to draw your attention to the type of rendering that you use.

Due to a lack of industry cohesion on the topic, most development projects out there still use the tried and trusted sand and mortal render approach. While all this is all well and good in the short run, it can be disastrous in the long-run.

A lot has been made about the fibre glass providing a wall much needed flexibility. If we simply put mortar on the wall, would that have provided us with the desirable outcome further down the line? The answer is simply no. Without the flexibility, your new shiny wall will probably show signs of hairline cracks within 18 months. Further down the line those cracks may open up and it could be much worse.

Although using fibre glass in the system will add a bit more work and be slightly more expensive to the traditional route, you are actually investing for the long-term and saving yourself a lot of headaches.

5 comments

Well, This is very helped us and useful to all. I am very happy to get this and very impressive thing that you mentioned in the article. Thanks for sharing this post.

I like your site, You made a good site and giving us the best information and posts they very clear I am impressed by your site and thoughts they very useful. Thanks for sharing the posts and designs they amazing I got them and very satisfied with your site

http://www.firstlook3dstudio.com/

Thanks for sharing the best posts they very useful to us. You made this site is awesome and you giving us such a great information on this topic, it’s very interesting one. I am very satisfied with your site and very nice.

Hi,

Do you double mesh or use high strength mesh on jobs?

Anibal

Hi Anibal,

We can do either depending on the job in question, but usually we get in high strength ‘panzer mesh’ for the job. It’s a bit more expensive but provides the best result.

Best,

Alan