How to Deal with Cracks in Brickwork Before Rendering

We come across many older properties with brickwork in really poor condition. This might be because the brickwork has become cracked and damaged over the years due to exposure from the elements, it could be due to structural issues within the building, or it could be where the old render has been removed, and damage has been caused to the brick underneath. In many cases where the old render is removed, the bricks underneath are substandard and in desperate need of repair.

What has caused the cracks?

As part of our initial survey, we will look at any cracks in the brickwork to see what has caused them. In some cases where we suspect a structural issue, we might recommend a survey from a structural surveyor to ensure there is no more serious issue. In this case, rendering would not make sense until the problem is resolved.

If the damage is superficial or easily remedied with some levelling mortar, we may be able to repair this as part of the job.

Levelling out surfaces before insulation and render

If there are uneven surfaces, that could cause cavities when covered with insulation or create an uneven base coat in render-only jobs, we will sometimes recommend levelling out the surface with a specially designed levelling mortar. This will ensure that you have a quality surface to render onto.

Strengthening brickwork before rendering

If the damage is severe but not structural, we suggest adding a strengthening metal mesh. As seen in the photo, this metal mesh is fixed mechanically to the brickwork to hold the brick together and ensure a stable surface to render onto. We would then cover the mesh with a mortar layer before proceeding with the regular basecoat, fibreglass mesh, and top coat.

Why do we ensure stable brickwork?

Many rendering companies would not bother to carry out this strengthening work. Still, we insist upon it because we have to offer you a long-term warranty (10 years for render only and 25 years for insulation and render). Without this groundwork, you are more susceptible to cracking and failure of the render system, so don’t take the second best option here.

Does strengthening the brickwork cost more?

The cost will depend on the amount of brickwork affected by the cracking. If much of the wall needs to have metal mesh, there will be a reasonably considerable increase in cost. If it is only a patch here and there, the price will only be a few hundred pounds. Well worth that extra investment to ensure a long-lasting finish.

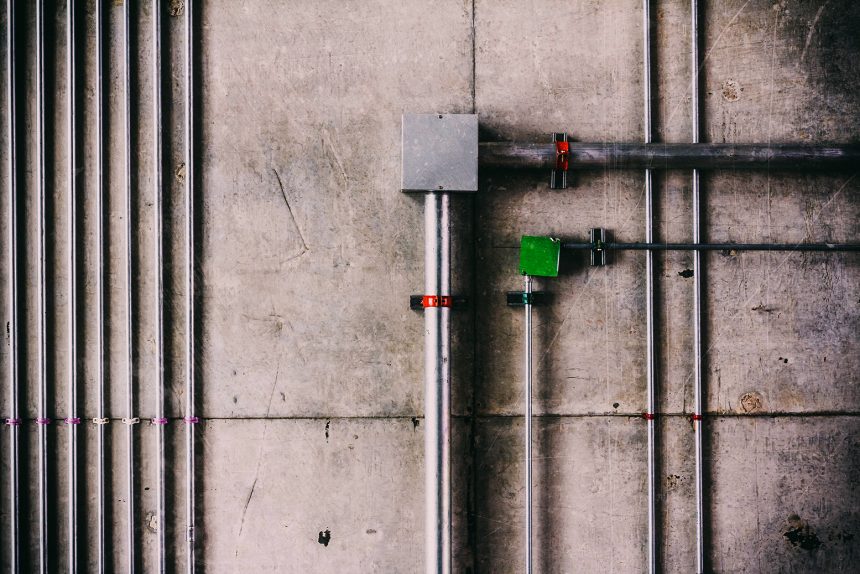

Burying cables in the insulation

Burying cables in the insulation