External Wall Insulation East Anglia

If you live in East Anglia, external wall insulation could be well worth installing. Whether you live in a rural area or a town or city, external wall insulation has a number of advantages.

While there is no ‘typical’ East Anglian house, it is safe to say that external wall insulation can add value to nearly all of them. Whether it’s an old building which was not built to be efficient, or a more modern property in need of some TLC, external wall insulation could be the answer. Maybe you already have cavity wall insulation, but it’s not quite doing the trick, or maybe your solid walls mean other forms of insulation are impossible. Old, new, terraced, detached, cavity or solid walled properties – external wall insulation can be installed on all of them.

Having said this, East Anglian properties are a diverse mix between the older properties in the centre of towns like Ipswich, Colchester and Norwich, with newer developments clustered around newer towns like Basildon and Harlow. The older towns tend to have a larger clustering of older period properties with solid brick walls, whereas the newer towns have a construction that tends to be quite diverse – solid walls, cavity walls (unfilled), cavity walls filled, timber frame construction, metal frame, etc

As you will know if you live there, it is pretty windy on the East Coast! Insulating your external walls can really improve your home’s ability to retain heat, and therefore keep you and your family warm.

With the uncertainty of energy prices out of your control, it is important to save money off your household bills where you can. External wall insulation will greatly increase the thermal efficiency of your home, meaning it retains warmth rather than leaking expensive heating out into the street.

Installing external wall insulation will also help to soundproof your walls, as the insulation materials used absorb sound waves as well as heat. It can be a great option for urban areas with a lot of traffic noise. In this case the best product is the stone wall or the mineral wool based external wall insulation system for soundproofing as the fibres on the insulation itself absorb most of the noise pollution.

The External Wall Insulation Process

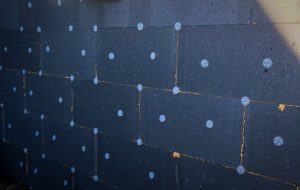

Installing external wall insulation is basically like wrapping your house in a blanket. First an insulating material, like EPS (expanded polystyrene) or mineral wool, is attached to the walls (using mechanical fixings and adhesive), then the outer layers are sealed with flexible beading and a high quality, breathable render product.

But keeping your house warm is not the only benefit of external wall insulation. Unlike other insulation options, it can also protect the outer leaf of the property from driving moisture and rainfall, reduce the risk of future interstitial condensation (trapped moisture within the fabric of the walls), and smarten up the outside your home. If, for instance, your property is covered in tired pebbledash or flaking render, external wall insulation is a great chance to give it a facelift!

Combine with Other Building Work

With a bit of planning, you can save on some of the fixed costs of external wall insulation. If you are undertaking other retrofit projects such as a loft extension, you can probably use the same scaffolding if you install external wall insulation at the same time. These kinds of building work generally require scaffolding being up for weeks until the works are complete, and there is no point paying for it twice.

While external wall insulation is not cheap, it is a long term investment that will save you money for years to come.

| Property type | Estimated Energy Costs (gas & electricity) | Estimated annual savings with EWI |

| Mid-terrace | £1,649 | £131 |

| Semi-detached | £2,049 | £308 |

| Detached | £2,370 | £472 |

Assumptions (data sourced from: TheGreenAge website):

1. Using EPC data for typical properties in the Essex County area.

2. Property scaling: 90m2 area property with partial double glazing, 75mm of loft insulation and a non-condensing boiler.

We are also very grateful to EWI Store Ipswich, who are a specialist external wall insulation materials supplier in the East Anglia area, who have helped us with product training and sourcing quality materials at a reasonable cost. They regularly have customers, architects and developers come around to have a look at the facilities and inspect the possibilities available with external wall insulation retrofit or application to new properties.

Michael, one of the store managers there, says:

We have specifically set-up shop in East Anglia England to potentially help spread the delivery of external wall insulation to Essex, Suffolk and beyond. Although our day-to-day services are mainly aimed at the specialist trade, we are always happy for end customers to pop-in and ask any questions about the external wall insulation process.

FYI – you can come to EWI Store anytime from 8am to 6pm Monday to Saturdays, and have a look at the samples of products as well as the reading literature available with more information.

Can I Organise a Quote for External Wall Insulation if I live in East Anglia?

Since 2014, we have been working in close collaboration with EWI Pro Insulation Systems, K-Rend and others – all specialist external wall insulation manufacturers and BBA approved system certificate holders. If you would like to see some of our local work, we can email you over some photos or you can view the projects on our website.

If you would like us us to help you organise a quotation for potential external insulation works, just get in touch! We don’t have to come out to see you straight away, but can organise a desktop quotation no problem and provide you with an indication of costs, to check whether the works would be suited to your budget. Simply contact us or send us an email with some property details, like the measurements of the height and width of the walls, with some photos, and we should be able to turn around the quote in less than 48 hours.